Low friction coatings: Anti-Friction coatings, AFC

Anti-friction coatings

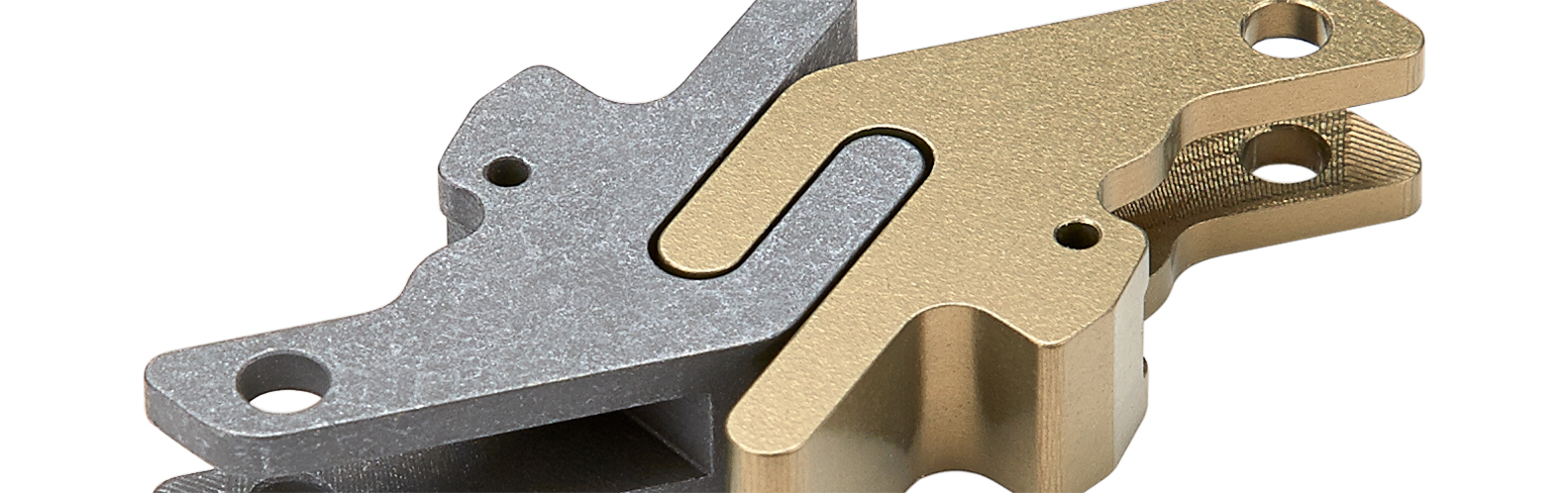

Anti-friction coatings provide surfaces, which are used in many ways advantageously within industry due to their friction-reducing and corrosion-preventing effect.

Anti-friction coatings

Antifriction coatings (AFC) are paint-like materials which contain solid lubricant particles in nanoparticle size. This allows coatings which provide a smooth surface even when viewed microscopically, and reduce friction to a minimum even under extreme conditions.

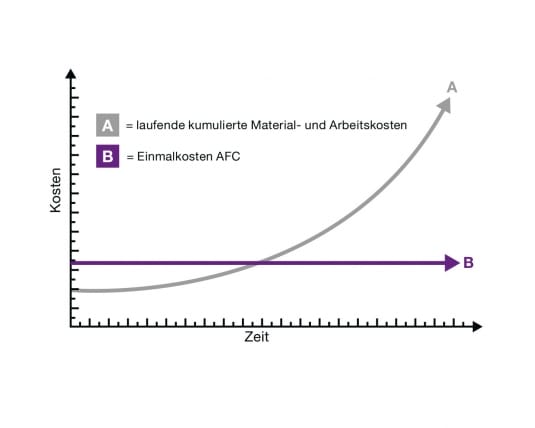

Whether for products made of metal, plastics or combined, anti-friction coatings are used for their properties wherever minimal wear and highest efficiency is required. Your advantage of an antifriction coating lies in the as yet unrecognised cost saving potential.

The quality of the anti-friction coating is determined by both the use of high quality materials as well as professional application. The antifriction coatings are applied in our facility with the aid of the latest application processes such as for example robots, mass small part coating systems and rotary spray machines.

Anti-friction coatings

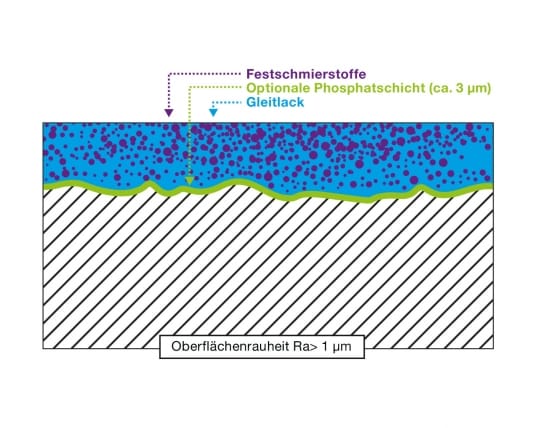

An anti-friction coating ensures that a surface is created which is especially smooth and therefore results in less friction. These properties arise as a result of the solid lubricant particles, which are the size of nanoparticles, which are present in the paint-like material of the antifriction coating.

As an option an approximately 3 µm thick phosphate layer is applied under the anti-friction coating. The resulting surface coating is extremely durable and also offers further advantages.

Anti-friction coating and its advantages in detail

- Thanks to the solid lubricant particles added to the paint, a large friction reduction and high loading capacity is achieved.

- The paint is also suitable for artefacts which will be used in extreme conditions. For example at temperatures between minus 200 °C and plus 600 °C, in a vacuum or in especially dusty environments.

- Oil or grease lubrication is ideally supported by this coating. This improves the running in of machine elements and emergency running properties are optimised.

- The paint is suitable for coating a wide range of materials. Metal coatings and plastic coatings are possible as well as the treatment of wood and elastomers.

- No contamination of friction points and the environment occurs - this means a high degree of cleanliness is reached and cleaning costs are reduced.

- Friction and vibration wear are substantially reduced.

- The coating with the special paint makes assembly of the associated parts easier.

- Since the maintenance efforts, including the reduced where, is minimised, a cost saving also results.

- The smoothness of the surfaces leads to a significant noise reduction.

- The corrosion protection which the coating provides is durable.

- Depending on the application lifetime lubrication without oil increase is possible.

Example applications

Anti-friction coatings have made a positive impact in many areas of industry, such as the reduction in friction, minimisation of wear and corrosion protection.

- Hinges

- Springs

- Gear wheels

- Sliding bearings

- Chain elements

- Spindles

- Linear guides

- Elastomer seals/ profiles

- Locks

- Sliding rails

- Shafts

- Hydraulic parts

- Pistons

- Switches

- Gears

- Screws, Nuts and bolts

Anti-friction coating compared with liquid lubricants

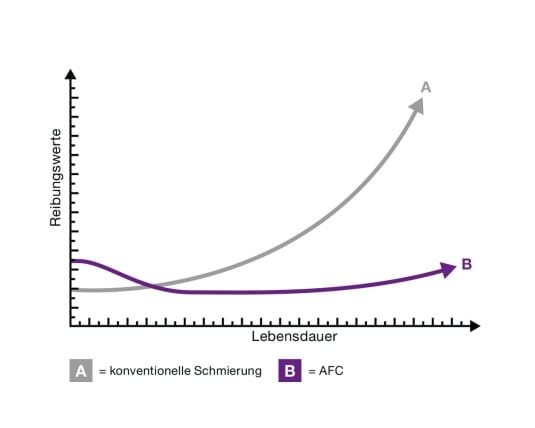

Further advantages of antifriction coating, which belongs to the family of dry lubricants, can be seen in a direct comparison with traditional liquid lubricants.

| Eigenschaften | Gleitlack | Flüssigschmierstoff |

| Niedrigtemperaturbereich | gut | ungünstig |

| Hochtemperaturbereich | sehr gut | nicht geeignet |

| Einsatz von Vakuum | sehr gut | fast unmöglich |

| Brennbarkeit | keine | hoch |

| Ionisierende Strahlung | gut | schlecht |

| Umweltgefährdung | sehr gering | hoch |

| Verunreinigung | gering | creep processes |

Would you be interested in having your parts coated with anti-friction coating?

We would be happy to advise you.

by phone:

+49 (0)711 139951 - 0

by E-Mail:

info@beschichtung.com

by online form:

to the online form